Overview

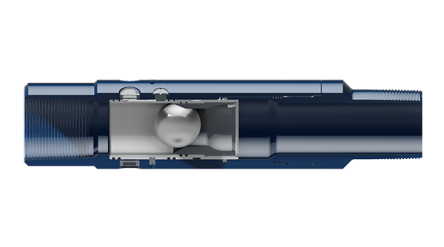

Tartan Completion’s EnerFrac™ single-entry, ball-drop system uses patented EnerFrac hydro-mechanical sleeves that are designed to stimulate individual stages at high rate. EnerFrac sleeves feature patent-pending BurstPoint™ ports, which fully open by increasing hydraulic pressure after the sleeve is shifted by an activation ball. This instantaneously releases the energy stored by the hydraulic pressure in the tubing to provide a more penetrating treatment, resulting in a deeper fracture network and increased production.

No communication with the wellbore exists until the BurstPoint ports are opened, which is then followed by the stimulation process. This “on-the-fly” operation enables quick completion of the well stimulation, increasing efficiency and reducing costs.

Application

- Single design for open hole or cemented liner installations

- Applicable for conventional and acid fracturing

- Stimulation of individual stages at high flow rates

Features and benefits

- BurstPoint ports prevent cement from entering the sleeve from the annulus, enabling unprecedented reliability in a cemented sliding sleeve

- Surface pressure indications are an accurate monitor of tool performance

- Rugged design for enhanced reliability

- Can be rotated to bottom

- Designed to handle the high torque capabilities of all premium and semi-premium connections

- Ball seats are designed for quick mill-out times

Fill out your information to receive the EnerFrac™ System data sheet.

Case Studies

MULTIFRAC™ D-J BASIN

Tartan MultiFrac systems successfully stimulated 18 months post-install.

ENERFRAC™ MONTNEY

Tartan successfully completes cemented EnerFrac™ ball-drop systems in the Montney.

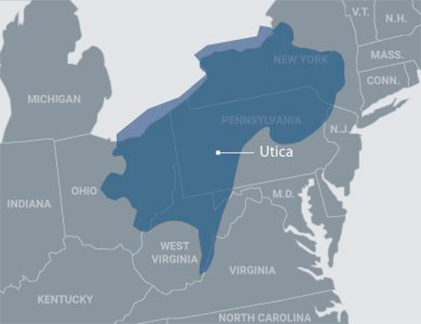

MULTIFRAC™ UTICA

Tartan cemented MultiFrac limited entry ball-drop systems increase production by 12.5%.