Overview

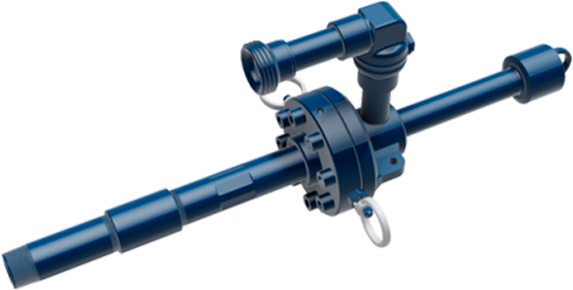

Tartan provides a few variations of coil connectors. Some incorporate multiple slips and some are just a straight Dimple Connector. One thing they all have in common is the use of dimple screws in addition to the slips to take up the torque of the drilling motor.

To increase worker safety, Tartan has designed the ARD so that it does not have any external moving parts exposed to the service rig personnel. The ARD also acts as the circulating head with flow passages and screens, which allows fluid to be circulated to operate the motor.

External Coil Connectors

Tartan’s External Coil Connector provides a means of connecting the coiled tubing to the bottom hole assembly (BHA) by attaching to the outside diameter (OD) of coiled tubing. Tartan’s design incorporates multiple slips with dimpling screws to set the connector.

Internal Coil Connectors

Tartan’s Internal Coil Connector provides a means of connecting the coiled tubing to the bottom hole assembly (BHA) by attaching to the inside diameter (ID) of coiled tubing. This connector is especially common on smaller OD drilling BHAs, but is also used when there is a smaller wellbore ID that has to be passed through.

FEATURES AND BENEFITS

External Coil Connectors

- Engages with the OD of the coiled tubing

- Uninterrupted bore for ball drop operations

- Slip ensures the axial load is transferred into the coiled tubing, increasing the strength of the connector grip

- Dimples give it more integrity to the coiled tubing and provide anti-rotational torque to connector

- Comprises a top and bottom sub, which contains the slip and spacer ring

- Locking screws prevent back-off of the service connection

- Anti-rotation screws prevent connector rotating once assembled

- Elastomeric seals

- Minimal coil dress required

- Field redressable

Internal Coil Connectors

- Robust and cost effective means of attaching a BHA to the coiled tubing

- Connector assembly ensures a positive connection to the coiled tubing

- Available for 1.250 in. to 2.875 in. coiled tubing sizes

- One-piece design provides superior mechanical strength

- Available with standard thru tubing tool joints or specially cut to customer requirements

- Two O-ring grooves provide added security in high-pressure applications

- Dimple design provides torque-through capabilities

- Reusable connectors furnished with standard O-rings simplifying field redress

Fill out your information to receive the Anti-Rotation Device and Circulating Head data sheet.

Case Studies

MULTIFRAC™ D-J BASIN

Tartan MultiFrac systems successfully stimulated 18 months post-install.

ENERFRAC™ MONTNEY

Tartan successfully completes cemented EnerFrac™ ball-drop systems in the Montney.

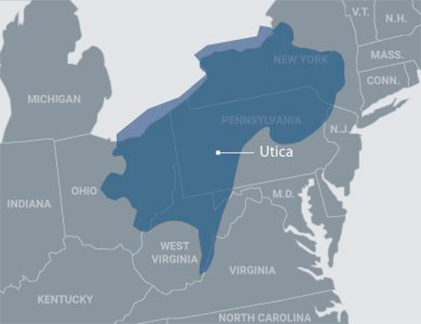

MULTIFRAC™ UTICA

Tartan cemented MultiFrac limited entry ball-drop systems increase production by 12.5%.