Overview

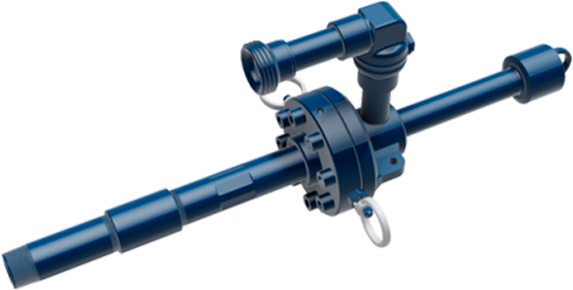

Tartan’s patented Anti-Rotation Device (ARD) controls and releases reactive torque generated from the use of down hole drilling motors. The ARD mechanically removes the reactive torque from the tool string at the rig floor.

To increase worker safety, Tartan has designed the ARD so that it does not have any external moving parts exposed to the service rig personnel. The ARD also acts as the circulating head with flow passages and screens, which allows fluid to be circulated to operate the motor.

Application

- Controls reactive torque when completions drilling with service and workover rigs

Features and Benefits

- Mechanically removes reactive torque at surface

- No external moving parts

- Extremely safe for rig personnel

- Very reliable in all working conditions

- Includes a circulating head for fluid delivery

- Equipped with flow passages and screen

- Provides costs savings

- No power swivel is required

- Short rig up/down time – 20 min vs. 60+ min

- No minimum rental charges

- No casing damage by rotating tubing

- Improved efficiency

- No collars required

- Minimizes pinch points

- No connection over-torque issues

Fill out your information to receive the Anti-Rotation Device and Circulating Head data sheet.

Case Studies

MULTIFRAC™ D-J BASIN

Tartan MultiFrac systems successfully stimulated 18 months post-install.

ENERFRAC™ MONTNEY

Tartan successfully completes cemented EnerFrac™ ball-drop systems in the Montney.

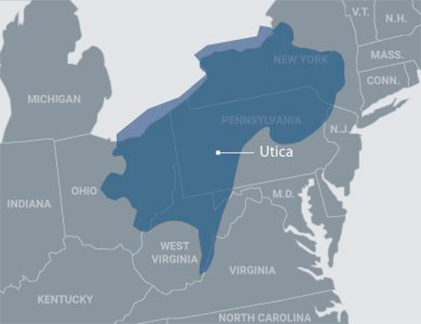

MULTIFRAC™ UTICA

Tartan cemented MultiFrac limited entry ball-drop systems increase production by 12.5%.