Overview

Tartan’s ultra low-friction engineered polymer centralizer (Slip ‘N Slide) is used during casing running and cementing operations. The Slip ‘N Slide ensures casing strings efficiently reach total depth, provides optimal standoff for mud displacement, and enhances cementing operations.

Made of advanced engineered polymers, the one-piece centralizer has an extremely low coefficient of friction, is highly durable as well as wear and heat resistant. The polymer material performs even in the most extreme wellbore conditions and is designed to easily pass challenging obstructions making it optimal for both cased hole and open hole extended horizontal applications. Unlike many plastics and bow spring centralizers, this centralizer withstands high-impact loading and is highly wear resistant.

Features and benefits

- Unmatched friction, rotational torque and drag reduction

- Helps extend the current well construction boundaries on extended reach drilling and highly deviated wells

- Spiraled line-of-sight blade design has proven for better cementing jobs without any of the typical debris removal risks

- Proven standoff at TD

- Improved fluid dynamics

- Provides a bearing to ensure casing and liners reach target depth

- Able to reduce the amount of lubricants used

- Increases the probability of casing reaching bottom without rotating

- Patent pending hybrid blade design offers the optimal mix of cementing turbulent ow and anti-bulldozing of cuttings

- Can eliminate the need for other friction reduction tools

- Increases the chance of a successful cementing job and reaching TD

- Light weight for safe handling

- Easily millable

Fill out your information to receive the Slip ‘N Slide data sheet.

Case Studies

MULTIFRAC™ D-J BASIN

Tartan MultiFrac systems successfully stimulated 18 months post-install.

MULTIFRAC BALL DROP SYSYTEM

Tartan Cemented MultiFrac Limited Entry Ball-Drop System Reduces Stimulation Time by 5 Days per Well Compared to Plug-and-Perf in the D-J Basin.

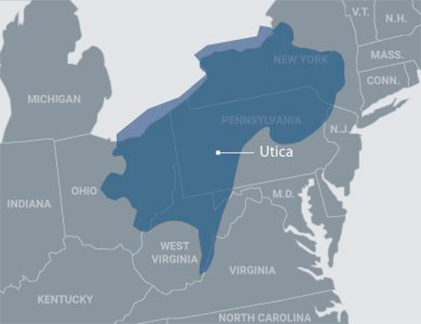

MULTIFRAC™ UTICA

Tartan cemented MultiFrac limited entry ball-drop systems increase production by 12.5%.