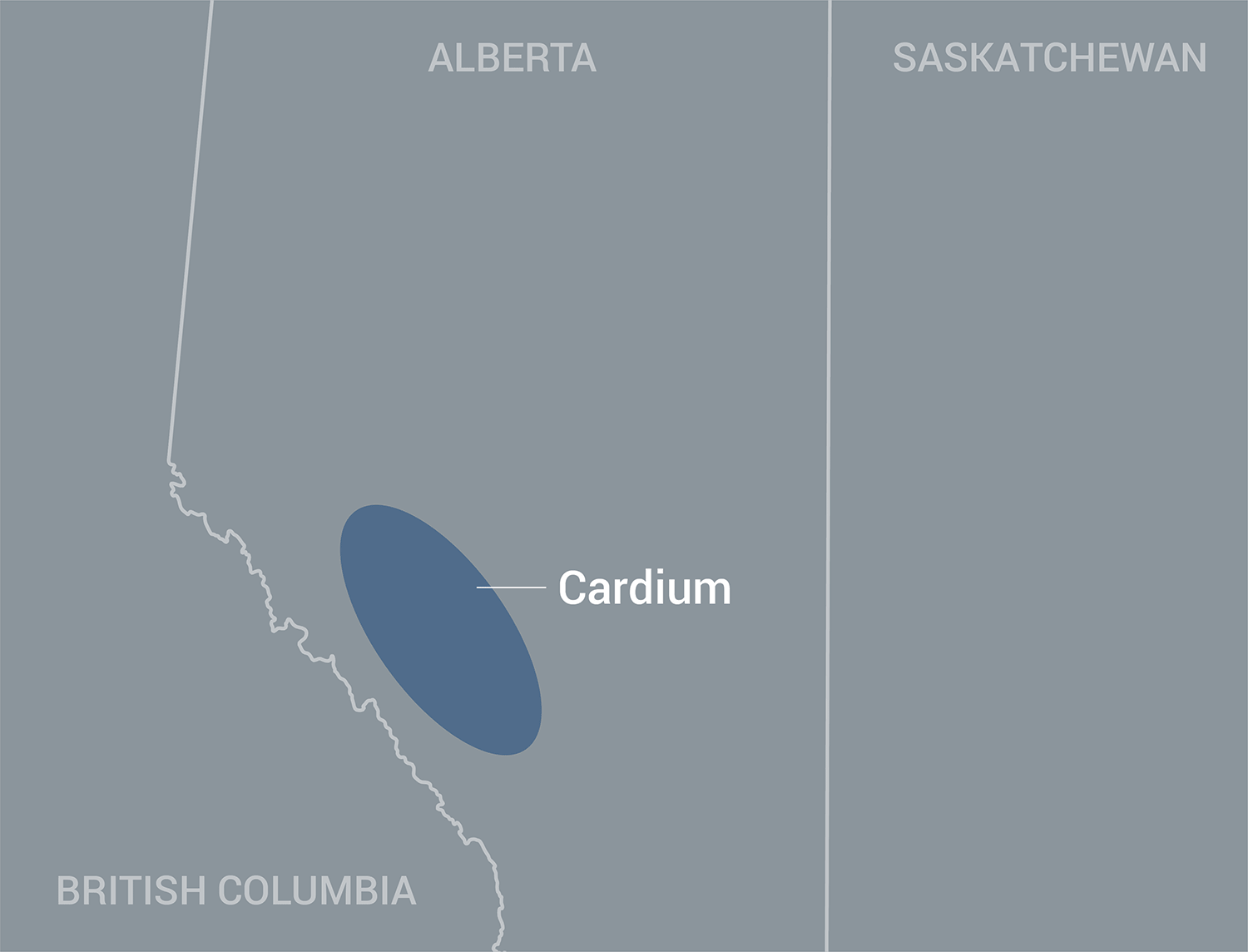

Cemented EnerFrac™ Ball-Drop System Cardium

Tartan Completes a 51-stage Cemented EnerFrac™ Ball-Drop System in the Cardium.

OBJECTIVE

An intermediate Canadian producer operating in the Cardium, wanted to capture the production advantages of a cemented completion system that was reliable and cost effective.

The producer realized production advantages in going from an open-hole completions system to a coil-activated cemented system, however, the operational costs of the coil system was very high. Tartan’s ball-drop cemented completions system represented the next step in producer’s search for a reliable and cost-effective cemented completions system that delivers optimal production results.

SOLUTION

Tartan proposed a cemented 51-stage EnerFrac™ single-

entry ball-drop system and Cemented Initiation Sub (CIS) technology for this producer’s 4800 m Cardium monobore well eliminated the need for the additional costs of running a stage tool and debris subs.

Tartan’s CIS reliably initiates stimulation at the toe, and both the CIS and EnerFrac™ sleeves feature BurstPoint™ ports that keep the system internals completely closed during installation and the cementing process, thereby enabling reliable stimulation operation by eliminating the risk of cement invasion into the sleeve mechanism.

RESULTS

Tartan’s cemented EnerFrac™ system, delivered flawless completion execution. All initiation balls seated properly. All frac ports opened reliably and allowed for successful formation stimulation.

The system used dissolvable balls. “On-the-fly” ball-drop operation enabled quick completion of the well stimulation, resulting in increased efficiency and reduced costs. The Cemented EnerFrac system saved the operator approximately $125,000 when comparing to previous cemented completions in this field.

This was the producer’s second well using Tartan Completions systems. Seeing repeatable positive results and increased production, the customer will use Tartan Completions for its upcoming drilling and completions program in the Cardium.